|

This is the way I pack MY trailer. The heck with those

other guys. My trailer is better than theirs. I start out with one-half of an upper wing

laying flat in the trailer. There are cut-outs in the floor of the trailer for

cabame/interplane strut attach tangs and aileron bellcrank- push rod. Note the high-dollar

Sears Best rug pad on the sides and bottom of the trailer. |

| Next, I put in the lower wings with padding between them

and the upper wing and themselves. A detachable pitot tube would be a nice thing but would

also add time to assembly and disassembly. You make the call. You can see the next big

layer of foam ready to roll on to separate the lower wings from the last upper wing half. |

|

|

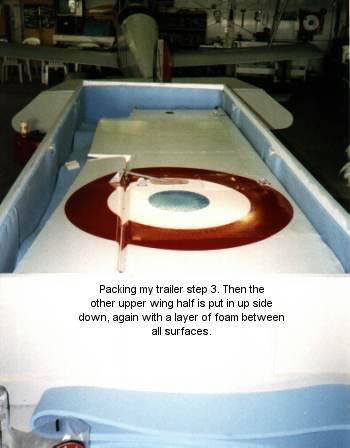

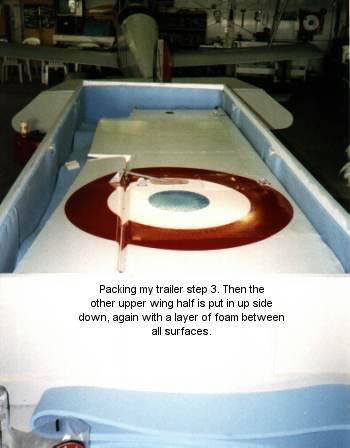

Then the remaining upper wing half is put in flat side up.

Note: the aileron horn/pushrod and interplane/cabane wing attach points are pointing up.

So, at this point, I put in some padded boards running from side to side for the

stab/elevator (which are left assembled, again to cut down on the time) to be sandwiched

between. |

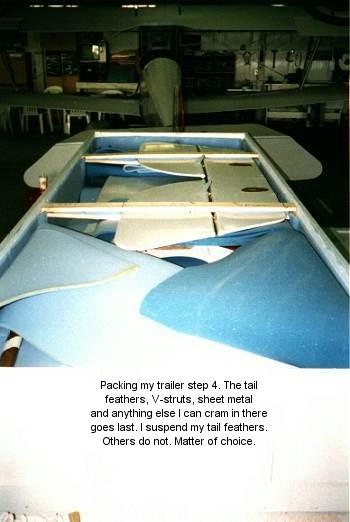

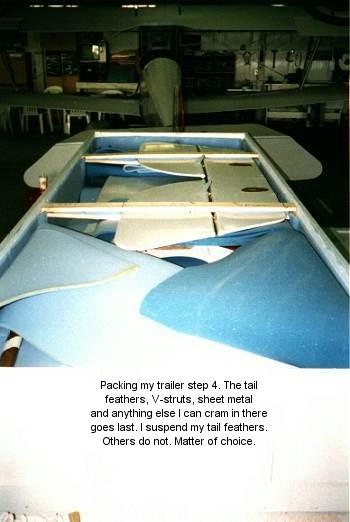

| Ready for the lid. The stab/elevator is captured between

the padded boards which are screwed into saddles on the side of the box. The boards keep

the elevator control horns from touching the upper wing half underneath. The rudder and

interplane struts are in foam "envelopes" and just placed in the trailer.

There's room for the gun, posters, wind shield and tools in the voids. IT REALLY WORKS

SWELL!!!!! |

|

"EAST BOUND AND DOWN... 18 WHEELS

A'TURNING,

WE GONNA DO WHAT THEY SAY CAN'T BE DONE!!"

Mark, Dick and I and our sweeties take a potty and Big

Mac break on the way to St. Louis. Can you believe that we got all 4 wings, tail surfaces,

tools, posters, guns, windshields and everything else in those little bitty boxes?

We drove through 40 mph wind gusts and blinding rain to get there....

BUT WE GOT THERE!!! AND FLEW THERE!!!... AND GOT HOME FROM THERE!!!

THROUGH DRIVING RAIN AND WIND AGAIN!!!

A husband and wife team can have a plane from

ready-to-trail to ready-to-fly in 1 1/2 hours. Mark, Dick and I with the wives had Dick

Lemon's plane ready to fly in one hour, 15 minutes. That ain't bad!

|

|

Dick and Sharon Lemons check over the final tie-down

before departing from St. Louis. The foam on the tail post keeps the rudder and elevator

cables from whipping against the fuselage while trailering. Note the tail wheel track on

the top of the trailer. Works great! |

| At the U.S. Air Force Museum's bi-annual WWI fly-in we

assembled the planes in the restoration facility's hangar. What a splendiferous

surrounding to work on a plane. It was a real hoot!!! I can't wait for the fly-in in 2003. |

|